In the demanding world of electric furnace steelmaking, the graphite electrode is more than just a component; it's the heart of the operation. It delivers the colossal energy needed to smelt tons of scrap steel, but it's also a significant operational cost. For any steel mill, managing graphite electrode consumption and, more critically, preventing catastrophic electrode breakage are paramount to maintaining profitability and production efficiency. A broken electrode doesn't just mean the loss of the electrode itself; it means costly downtime, potential damage to the furnace, and disruptions to the entire production schedule.

My name is Frank Liu, and for over 30 years at Hebei Heyuan New Material Technology Co., Ltd., I've specialized in manufacturing high-performance graphite electrodes. I've worked closely with procurement directors and metallurgists like Peter Kovac in Germany, who understand that the true cost of an electrode isn't its purchase price, but its performance and reliability in the furnace. This article is a culmination of that experience. We will dive deep into the causes of high electrode consumption and breakage and provide practical, actionable strategies to control them. This is a guide for professionals who value stability and want to optimize every aspect of their electric arc furnace operations.

Why is Graphite Electrode Consumption a Critical Factor in Electric Furnace Steelmaking?

In electric furnace steelmaking, the cost of graphite electrodes represents a significant portion of the variable production costs, often second only to electrical energy. Therefore, even a small reduction in the consumption of graphite electrode per ton of steel produced can have a substantial positive impact on a plant's bottom line. The use of graphite electrodes is inherently a consumptive process, but the rate of that consumption can vary widely.

Electrode consumption is measured in kilograms (or pounds) of graphite consumed per ton of steel produced. This figure is a key performance indicator (KPI) for any electric furnace shop. High consumption not only increases direct costs but can also be an indicator of underlying issues in the furnace operation, such as an inefficient power program, excessive oxidation, or poor quality raw materials. Managing this consumption is a continuous process of balancing electrical, chemical, and mechanical factors to achieve the most efficient smelt.

What are the Primary Causes of High Electrode Consumption?

High graphite electrode consumption is not a single problem but a combination of several factors. Understanding the different modes of consumption is the first step toward controlling them. The total consumption of the electrode is generally broken down into two main categories: tip consumption and sidewall consumption.

- Tip Consumption: This occurs at the very end of the electrode where the electric arc is generated. The intense heat of the arc (over 3,000°C) causes the graphite tip to sublimate, turning directly from a solid to a gas. This is a necessary and unavoidable part of the process, accounting for a large portion of the total electrode use.

- Sidewall Consumption: The body of the electrode column is exposed to the extreme heat and reactive atmosphere inside the furnace. Oxygen and carbon dioxide in the furnace can react with the graphite on the electrode sidewall, causing it to oxidize and wear away. This form of consumption can be managed and reduced through good operational practices, such as maintaining a foamy slag to shield the electrode.

A third, and most undesirable, form of loss is through breakage. While not technically "consumption," an electrode breaking event results in a massive and sudden loss of the electrode material and is the most costly type of electrode use accident.

How Does the Quality of the Electrode Directly Impact Performance?

The intrinsic quality of the electrode is the foundation upon which all operational efficiencies are built. A low-quality electrode will underperform and be prone to breakage, no matter how well the furnace is operated. For a procurement professional like Peter, understanding the key indicators of the electrode is crucial for making an informed purchasing decision.

Key quality parameters include:

- Low Electrical Resistivity: A high-quality electrode must have low resistance to allow electricity to flow freely to the tip. High resistance of the electrode causes it to heat up in the body, leading to increased sidewall oxidation and thermal stress.

- High Bulk Density: A denser electrode is stronger and more resistant to both mechanical stress and chemical oxidation.

- Good Flexural Strength: This measures the strength of the electrode and its ability to resist bending forces, which are common inside the furnace as scrap shifts. A weak electrode can easily break the electrode.

- Low Coefficient of Thermal Expansion (CTE): A low CTE gives the electrode superior thermal shock resistance. An electrode with poor thermal shock resistance can develop cracks and fail when subjected to rapid temperature changes.

"I've seen mills try to save a few dollars on a cheaper electrode, only to lose thousands in downtime when that electrode fails. The internal quality of the electrode, determined by the raw materials and manufacturing process, is non-negotiable. It is the single most important factor in ensuring stable and efficient furnace operations." - Frank Liu

What Operational Factors in the Arc Furnace Can Lead to Electrode Breakage?

While electrode quality is paramount, even the best graphite electrode can fail if subjected to poor operating conditions. The electric arc furnace is a violent, dynamic environment, and operators must be vigilant to avoid electrode breakage.

Common operational causes include:

- Scrap Cave-ins: As the scrap pile melts, it can become unstable and shift suddenly. A large cave-in can exert a powerful mechanical shock on the electrode, causing it to fracture, often at the electrode joint or in the middle of the electrode.

- Improper Electrode Regulation: The electrode regulator system is designed to maintain a stable arc length. If the regulator is too aggressive or malfunctions, it can drive the electrode into the scrap or molten bath, causing a short circuit and immense mechanical stress that can break the electrode.

- Electrode Clamping Issues: The electrode holder cannot be clamped too tightly, as this can crush the electrode, or too loosely, as this can cause poor electrical contact and arcing at the holder. Both conditions can easily cause the electrode to fail. There must be close contact with the electrode without excessive force.

- Non-conductive Material: If a large piece of non-conductive material (like slag or refractory) falls on top of the scrap pile, the electrode is automatically lowered until it makes contact. If it hits this obstruction, the resulting mechanical shock can be severe.

Why is the Electrode Joint the Most Vulnerable Point?

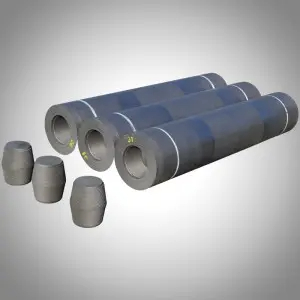

The electrode column in an electric furnace is made up of several individual graphite electrodes connected end-to-end by tapered graphite connecting pins, or nipples. This electrode connection point, known as the electrode joint, is the weakest link in the chain. The vast majority of electrode breakage incidents occur at or near a joint.

The graphite electrode and the joint must be treated as a single system. A perfect electrode can be compromised by a poor joint. If the joint and the electrode faces are not perfectly clean or if the nipple is not torqued to the correct specification, a gap can form. This gap increases electrical resistance, causing the electrode joint to overheat. The overheating weakens the nipple and the surrounding electrode material, making it highly susceptible to breaking under even normal operational stress. Ensuring a clean, properly torqued connection every time a new electrode is added is one of the most effective ways to prevent the electrode from failing.

How Do You Choose the Right Electrode for Your Furnace?

Selecting the right grade of graphite electrode is a critical decision that impacts both cost and performance. Using an electrode that is not matched to the power level of the furnace is a recipe for high consumption and failure.

- Regular Power (RP) Electrodes: Suitable for lower-power applications like ladle furnaces or some ferroalloy production.

- High Power (HP) Electrodes: Designed for higher-powered electric arc furnaces and offer better performance and lower consumption than RP grades.

- Ultra-High Power (UHP) Electrodes: This is the premium grade, made from high-quality needle coke. UHP Graphite Electrodes are essential for modern, high-productivity electric arc furnaces. They have the lowest electrical resistance and best thermal shock resistance, allowing them to handle the extreme current densities required to smelt steel quickly and efficiently.

For a modern steelmaking operation, using an ultra-high power graphite electrode is almost always the most economical choice in the long run. The higher initial cost is more than offset by a lower graphite electrode consumption rate and a significantly reduced risk of breakage. When you choose the right electrode, you are investing in operational stability.

What Practical Measures to Reduce Electrode Consumption Can Be Implemented?

Reducing electrode consumption requires a holistic approach that involves the entire steelmaking team. Here are some effective strategies:

- Optimize Foamy Slag Practice: A deep, foamy slag is the best protection for the electrode sidewall. It submerges the electric arc and shields the electrode column from the furnace atmosphere, dramatically reducing oxidation.

- Water-Cooled Panels: Ensure water-cooled panels are functioning correctly to protect the furnace walls, but also ensure they don't create excessive water vapor, which can increase oxidation of the electrode.

- Correct Electrode Clamping: Regularly inspect the electrode holder and ensure the electrode clamping pressure is set according to the manufacturer's recommendation.

- Minimize Air Ingress: Seal any gaps or leaks in the furnace shell to prevent excess air from entering. This "tramp air" is a major source of oxygen that aggressively attacks the hot graphite electrode.

- Power Program Optimization: Work with metallurgists to develop a "soft start" power profile that melts the initial bore-in path smoothly, avoiding excessive stress on the electrode.

What is the Role of the Electrode Regulator in Preventing Accidents?

The electrode regulator is the brain of the electric furnace's positioning system. It is a sophisticated hydraulic or electromechanical system that continuously adjusts the vertical position of each three-phase electrode to maintain a stable arc length and power input. A well-tuned regulator is crucial to avoid electrode breakage.

The system monitors the electrical parameters (current and voltage) of each phase electrode in real-time. If the current gets too high (indicating the electrode is too close to the scrap), the regulator raises the electrode. If the current is too low (arc is too long), it lowers the electrode. The responsiveness and stability of this system are vital. A sluggish or erratic regulator can cause the electrode to dip into the molten bath or be struck by shifting scrap. The drive mechanism of the electrode and the braking force of the electrode hydraulic system must be perfectly maintained to ensure the normal use of graphite electrodes.

How Should a New Electrode Be Properly Connected and Used?

The procedure for adding a new electrode to an existing electrode column ("jointing") is a critical control point. Rushing this process is a common cause of electrode use accidents are caused by joint failure.

The correct procedure is as follows:

- Inspect Both Electrodes: Before connecting, inspect the threaded sockets of both the lower electrode in the furnace and the new electrode. Look for any damage or debris.

- Clean Thoroughly: Use compressed air to clean the electrode sockets and the threads of the connecting nipple. Any dust or foreign material can compromise the connection.

- Proper Torquing: Use a calibrated torque wrench to tighten the electrode to the manufacturer's specified value. Under-tightening leads to a loose, high-resistance joint. Over-tightening can damage the threads and break the electrode socket.

- Careful Handling: Use lifting clamps and cranes carefully to avoid bumping the electrode against the furnace structure during installation.

- Gradual Power Increase: When the new electrode is first used, it's good practice to operate at a slightly reduced power for a short period to allow the electrode joint to thermally stabilize before applying full power.

Why is a Strong Supplier Partnership Key to Avoiding Electrode Breakage?

Ultimately, minimizing electrode consumption and preventing breakage is a collaborative effort between the steelmaker and the electrode supplier. A transactional relationship focused only on price is short-sighted. A true partnership with a reputable manufacturer like Hebei Heyuan New Material Technology Co., Ltd. provides layers of value that directly address the core pain points of a procurement director.

A good partner provides:

- Consistent Quality: A reliable manufacturer has robust quality control systems that ensure every electrode shipped meets the required specifications. This consistency is the bedrock of predictable furnace performance.

- Technical Support: An experienced supplier can offer technical advice on everything from proper jointing techniques to optimizing furnace power profiles for your specific operation. We understand the smelting process of graphite electrodes and the demands of your furnace.

- Traceability and Transparency: If an issue does arise, a good supplier can trace the electrode back through the entire production process to identify any potential anomalies.

- Reliable Logistics: A proven supplier has the experience to manage the complex logistics of shipping large, heavy, and relatively fragile graphite electrodes across the globe, ensuring they arrive on time and intact.

By working with a knowledgeable and reliable supplier, you are not just buying a product; you are investing in the stability and efficiency of your entire steelmaking operation.

Key Takeaways

- Consumption is a Major Cost: Graphite electrode consumption is a significant operational expense in EAF steelmaking, making efficiency crucial for profitability.

- Quality is Non-Negotiable: The internal quality of the electrode (resistivity, density, strength, thermal shock resistance) is the single most important factor in preventing breakage and reducing consumption.

- Joints are the Weakest Link: The vast majority of electrode breakage occurs at the electrode joint. Meticulous cleaning and proper torquing are essential.

- Operations Matter: Furnace practices, such as maintaining a foamy slag and ensuring proper electrode regulation, have a direct and significant impact on electrode life.

- Choose the Right Grade: Match the electrode grade (RP, HP, or UHP) to your furnace's power level. Using an under-specified electrode leads to rapid failure.

- Partnership Over Price: A strong relationship with an experienced and reputable supplier provides technical support and consistent quality, which is far more valuable than a low initial purchase price.

Post time: 10 月-20-2025