In the demanding world of electric furnace steelmaking, operational efficiency is paramount. Every component, every process, and every minute of downtime directly impacts the bottom line. Among the most critical and costly consumables are the graphite electrodes, the powerful heart of the electric arc furnace (EAF). Understanding and controlling graphite electrode consumption is not just a technical challenge—it is a financial necessity. This article provides a comprehensive guide to the main factors affecting the consumption of graphite electrodes, written from the perspective of a seasoned manufacturer for industry professionals who demand performance and reliability.

My name is Frank Liu, and for over 30 years at Hebei Heyuan New Material Technology Co., Ltd., I've dedicated my career to perfecting the art and science of manufacturing high-performance graphite products. I've worked closely with procurement directors like Peter Kovac in Germany, who know that minimizing electrode consumption per ton of steel is a key performance indicator. This guide is for him and for you. We will break down the complex interplay between electrode quality, furnace operations, and raw materials to give you actionable insights for optimizing your steelmaking process.

What Exactly is Graphite Electrode Consumption in an EAF?

Graphite electrode consumption refers to the amount of the electrode, measured in kilograms, that is consumed to produce one ton of liquid steel. It's a critical metric for any EAF operation, directly translating to production cost. This consumption isn't a single event; it's a combination of several mechanisms occurring simultaneously within the harsh environment of the furnace. The primary forms of consumption are tip sublimation (the end of the electrode turning to gas from the intense heat of the arc) and body oxidation (the sides of the electrode reacting with oxygen in the furnace atmosphere).

Understanding these mechanisms is the first step toward controlling them. A low consumption rate indicates an efficient, well-managed steelmaking process and a high-quality graphite electrode. Conversely, high consumption caused by any number of factors can dramatically increase costs and even signal underlying problems with the furnace or the operational procedures. The goal of every electric furnace steelmaking operation is to achieve the lowest possible consumption of graphite electrode without compromising the speed or quality of the smelt.

How Does the Inherent Quality of a Graphite Electrode Impact Its Lifespan?

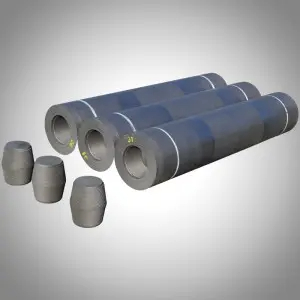

The first and most fundamental factor influencing electrode consumption is the quality of the graphite electrode itself. Not all electrodes are created equal. An electrode manufactured with superior raw materials and a meticulous process will consistently outperform a lower-quality one. Key properties that determine the consumption rate include electrical resistivity, bulk density, flexural strength, and thermal shock resistance.

At Heyuan Carbon, we know that using premium needle coke is essential for producing top-tier UHP (Ultra-High Power) electrodes. This raw material leads to a final product with lower electrical resistance, meaning less energy is lost as heat within the electrode body, reducing thermal stress. High density and strength prevent cracking and electrode breakage under the immense mechanical and thermal stresses inside the furnace. A superior electrode will have better oxidation resistance and thermal shock properties, leading to a slower rate of both side oxidation and tip sublimation. For a procurement director, investing in a higher-quality graphite electrode from a reputable manufacturer is a direct investment in lower, more predictable consumption of graphite.

Why is the Physical Condition of the Electric Furnace So Critical?

The electric arc furnace is the environment where the electrode performs its job, and the condition of this furnace has a massive impact on electrode consumption and loss. A poorly maintained furnace can wreak havoc on even the best electrodes. For instance, a furnace with significant air leaks will have a highly oxidizing atmosphere. This excess oxygen will aggressively attack the hot surface of the electrode, dramatically increasing the rate of side oxidation. This is one of the primary reasons for excessive consumption.

Furthermore, the alignment of the electrode columns is critical. If the clamps and arms are misaligned, they will put uneven mechanical stress on the electrode column, leading to a higher probability of breakage, especially at the joints. The water-cooled panels in the furnace walls and roof must also function correctly. If they fail, the refractory can be damaged, leading to a less efficient smelt and longer power-on times, which in turn increases the total time the electrode is in this furnace and exposed to oxidation. A regular furnace maintenance schedule is essential for protecting your investment in electrodes.

What are the Main Factors in the Smelting Process that Affect Graphite Electrode Consumption?

The operation of the smelting process is a dynamic and complex variable that directly influences the rate of consumption of electrodes. How the operators run the furnace can either preserve or destroy the electrodes. One of the most significant factors is the length of the smelting cycle. Longer power-on times mean the electrodes are exposed to the high temperature and oxidizing atmosphere of the furnace for a longer duration, leading to higher consumption.

Another critical operational factor is oxygen blowing. While oxygen blowing is essential for decarburization and accelerating the smelt, excessive or poorly aimed oxygen lances can directly impinge on the electrode surface, causing rapid, localized oxidation and "necking." The design of the foaming slag practice is also important. A good, deep foaming slag will cover the electric arc and the lower portion of the electrode, shielding it from the furnace atmosphere and reducing both radiant heat loss and oxidation. A skilled furnace operator knows how to balance a fast smelt time with practices that protect the electrodes.

"In my experience, the difference between a good furnace operator and a great one can be measured in kilograms of graphite electrode saved per smelt. The best operators understand that the electrodes are a tool to be used efficiently, not just a brute-force heat source." - Frank Liu

How Does Oxidation Contribute to the Loss of Graphite?

While the electrode tip sublimates from the heat of the arc, the greatest loss and consumption of graphite—often up to 50% of total consumption—comes from oxidation. This is the chemical reaction between the hot carbon of the electrode and oxygen (O2) or carbon dioxide (CO2) in the furnace atmosphere. The electrode surface essentially burns away, much like a log in a fire, but at a much higher temperature. The rate of oxidation increases exponentially with temperature.

The oxidation occurs over the entire length of the electrode column inside the furnace. The hot gases circulating in the furnace attack the electrode body, reducing its diameter over time. As the diameter shrinks, its electrical resistance increases and its mechanical strength decreases, making it more susceptible to breakage. This is why minimizing air ingress into the furnace and maintaining a good foaming slag to shield the electrode are paramount. Some modern electrodes come with protective coatings designed to reduce oxidation, but operational practice remains the first line of defense. The stability of graphite electrode performance is heavily tied to controlling the furnace atmosphere.

Can Improper Electrode Connections and Handling Lead to Breakage?

Absolutely. Electrode breakage is one of the most catastrophic and costly events in EAF operations, and it often stems from issues with the electrode connection. The electrode column in a large furnace is made of several individual electrodes joined together by tapered, threaded connectors called nipples. The integrity of this joint is crucial. If the joint is too loose, the contact resistance will be high, causing it to overheat and fail. If it is too tight, the excessive torque can crack the electrode socket.

The impact of a proper electrode connection is very obvious. It ensures a smooth flow of current and provides the necessary mechanical strength to lift and lower the entire column. The accuracy of the electrode and nipple machining is vital here, which is why sourcing high-quality Graphite Electrode Nipples that are perfectly matched to your electrodes is non-negotiable. Breakage not only results in the loss of large sections of the electrode but can also lead to significant downtime, damage to the furnace, and potential contamination of the molten steel. Proper torqueing procedures and careful handling during assembly are essential preventative measures.

How Does the Furnace Power Supply System Influence Electrode Consumption?

The power supply equipment for an electric arc furnace is responsible for delivering the immense energy required to smelt steel, and its characteristics directly affect graphite electrode performance. The stability of the power supply is key. If the voltage and current are erratic or the fluctuation is too large, it can lead to an unstable arc. This instability can cause thermal shock and mechanical vibration in the electrode, increasing the risk of cracking or breakage at the electrode tip.

Furthermore, the power supply profile, or the transmission curve and gear, must be optimized for the specific type of scrap being used and the phase of the smelt. Using a power profile that is too aggressive early in the smelt when the scrap is not yet melted can lead to frequent cave-ins, which can strike the electrodes and cause mechanical breakage. If the current is too high for the electrode's diameter, it can exceed the limit load of the electrode, causing it to overheat and increasing the rate of consumption of the electrode. The capacity of the power supply must be matched with appropriately sized and graded electrodes.

Does the Quality of Scrap Steel Affect How the Electrodes Perform?

Yes, the type and quality of the scrap steel used as the raw material play a significant role. The density of the scrap charge affects the initial "bore-in" phase of the smelt. Light, low-density scrap can be more difficult to establish a stable arc on and may require a longer smelting time, increasing overall electrode consumption. Conversely, very heavy or large pieces of scrap can shift and cave in during the smelt, creating a high risk of mechanical impact and electrode breakage.

The chemical composition of the scrap also matters. Non-conductive materials mixed in with the scrap steel can interfere with arc stability. The goal is to use a consistent, well-blended mix of scrap to ensure a predictable and efficient smelting process. Some modern furnace practices, like hot charging of direct-reduced iron (DRI) or hot metal, can also change the dynamics of the smelt and require adjustments to the power program to optimize the service life and consumption of the electrodes in electric arc furnaces.

What is the Difference Between Tip Consumption and Body Oxidation?

It's helpful to break down graphite electrode consumption into two main categories, as managing them requires different strategies.

| Consumption Type | Location | Primary Cause | Key Influencing Factors |

|---|---|---|---|

| Tip Consumption | The very bottom of the electrode (electrode tip or electrode end face) | Sublimation (turning from solid to gas) due to the extreme heat of the electric arc (>3,000°C). | Arc current, arc length, smelting time, foaming slag quality. |

| Body Consumption | The sides (electrode body) of the electrode column inside the furnace. | Oxidation from reaction with O2 and CO2 in the furnace atmosphere. | Air ingress into the furnace, oxygen blowing practices, power-on time, electrode's inherent oxidation resistance. |

While tip consumption is an unavoidable part of the melting process, it is relatively predictable. Body oxidation, however, can be highly variable and often represents the largest potential for savings. By focusing on sealing the furnace, optimizing slag practices, and controlling oxygen lancing, a steel mill can significantly reduce this portion of its electrode consumption.

How Can You Partner With Your Supplier to Minimize Consumption?

Reducing electrode consumption is a collaborative effort. An experienced and technically proficient supplier is more than just a vendor; they are a partner in your efficiency goals. A strong partnership can help address the many factors that contribute to consumption. At Hebei Heyuan, we believe in this partnership model.

First, a good supplier provides consistently high-quality graphite electrodes, like our UHP Graphite Electrodes, which form the reliable foundation of your operation. Second, they provide technical support. Our team understands the steelmaking process and can help analyze your furnace data to recommend the optimal electrode grade and operating practices. This helps overcome the pain point of dealing with sales staff who lack deep technical knowledge. Finally, a reliable partner ensures robust logistics and on-time delivery, so you never have to worry about production disruptions. By working together, we can analyze the specific factors affecting consumption in your furnace and implement strategies to control them, ultimately lowering your cost per ton of steel.

Key Takeaways

Controlling graphite electrode consumption is a multifaceted challenge that requires a holistic approach, addressing everything from the quality of the electrode to the specifics of the furnace operation.

- Quality is Foundational: The single most important factor is the quality of the graphite electrode. Investing in electrodes with low resistivity and high thermal shock resistance provides the best defense against consumption.

- The Furnace is the Environment: A well-maintained, well-sealed furnace with properly aligned columns is essential to minimize oxidation and prevent mechanical breakage.

- Operations Dictate Performance: The skill of the furnace operators in managing the smelting cycle, foaming slag, and oxygen blowing has a direct and immediate impact on electrode life.

- Oxidation is the Biggest Enemy: The majority of controllable electrode loss comes from side oxidation. Controlling the furnace atmosphere is key to minimizing it.

- Partnership Drives Efficiency: Work closely with a knowledgeable supplier who can provide not only a consistent, high-quality product but also the technical expertise to help you optimize your entire electric furnace steelmaking process.

Post time: 10 月-10-2025