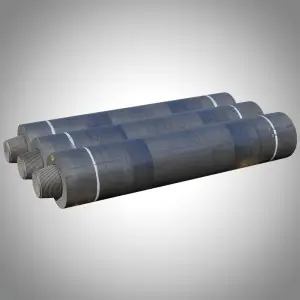

Imagine standing on the catwalk of a steel mill. The heat is intense. The sound of the electric arc furnace (EAF) is a deafening roar as it melts through tons of scrap metal. In this chaotic environment, the entire operation relies on one critical component: the graphite electrode. If that electrode fails, the roar stops. Production halts. Money burns away not in the furnace, but in downtime.

My name is Frank Liu. For over 30 years, I have been part of the heartbeat of the carbon industry at Hebei Heyuan New Material Technology Co., Ltd. I have seen the evolution of furnace technology and the increasing demands placed on electrode material. I know that for professionals like you—perhaps a procurement director named Peter who values precision and reliability—choosing the right graphite electrode is not a gamble. It is a science.

But how do you really know if what you are buying is good? You cannot just look at a black cylinder and judge its worth. You need to look at the data. Today, we are going to dive deep into the technical parameters that define quality. We will explore how to measure the quality of graphite and ensure you are getting power graphite electrodes that withstand the test of fire.

Unveiling the Secrets of High Power Graphite Electrode Quality

The graphite electrode is often called the "conductor of the industry." It transfers massive amounts of electrical energy into the furnace to melt steel. But not all electrodes are created equal. To the untrained eye, a standard electrode looks just like a high power graphite electrode. However, their performance in the furnace will be vastly different.

To measure the quality of graphite, we must look beyond the surface. We must analyze the physical and mechanical properties. These properties tell us how the electrode will behave under extreme heat and stress. A high-quality electrode material must balance contradictory traits: it needs to be soft enough to machine but strong enough to hold tons of weight. It must conduct electricity well but resist heat flow.

When we talk about measure the quality of graphite, we are looking at a specific set of main indicators. These include resistivity, density, mechanical strength, and the thermal expansion coefficient. Understanding these numbers is the key to preventing breakage and reducing the consumption of graphite per ton of steel.

Why is Electrical Resistivity the Critical Parameter?

The primary job of an electrode is to conduct electricity. Therefore, resistivity is arguably the most important parameter. Resistivity measures how strongly a material opposes the flow of electric current. For a graphite electrode, we want this number to be as low as possible.

Low resistivity means high conductivity. It allows the electric current to flow freely through the electrode column and into the melt. If the resistivity is too high, the electrode acts like a giant heater. The energy that should be melting the steel is instead wasted heating up the electrode body. This causes the electrode to turn red hot, oxidize rapidly, and potentially crack due to thermal stress.

We measure this using the voltage drop method. By passing a known current through the electrode and measuring the voltage drop, we calculate the resistance. Power graphite electrodes must meet strict low-resistivity standards. For ultra high power graphite (UHP), the requirements are even stricter because the current density is massive. A lower resistance of a conductor like graphite means a more efficient furnace.

How Does Bulk Density Impact the Performance of the Electrode Column?

Density is a tricky parameter. You might think, "the heavier, the better," but it is a delicate balance. Density refers to the mass of the graphite per unit volume. Generally, a higher density indicates a stronger, more robust electrode.

Higher density usually means better mechanical properties and higher electrical conductivity. It also helps with oxidation. Oxygen attacks porous materials faster. A dense surface leaves fewer openings for oxygen to penetrate, improving the oxidation resistance and thermal shock capabilities.

However, if the density is too high, the material can become brittle. It might lose its ability to handle thermal shock resistance of graphite. This is where manufacturing expertise comes in. We aim for a "sweet spot" where the density is high enough for strength and conductivity, but the structure remains resilient. This balance is vital to enhance the reliability of electrode performance in your EAF.

Why is Mechanical Strength Essential for Electrodes in Electric Arc Furnaces?

Inside an electric arc furnace (EAF), the environment is violent. Scrap metal collapses. The arc forces vibrate the column. The graphite electrode must withstand these physical assaults. This is why we test for mechanical strength.

We look at two main types: flexural strength (bending) and compressive strength (crushing). Flexural strength is critical because the electrode column is long and thin. Lateral forces from moving scrap can snap a weak electrode in half. Electrodes with high flexural strength are much more resistant to these accidents.

The mechanical strength of graphite electrodes is directly related to the raw material and the manufacturing process. Using high-quality coke and precise baking cycles creates a strong internal bond. If the mechanical properties are poor, you will see frequent breakage at the joints or in the body, leading to costly downtime.

What Role Does Thermal Expansion Coefficient Play in Avoiding Breakage?

This is a term that technical buyers like Peter pay close attention to: Thermal Expansion Coefficient (CTE). When you heat materials, they expand. When you cool them, they shrink. In a furnace, the temperature can jump from room temperature to over 3,000°C in minutes.

If a graphite electrode expands too much, it creates massive internal stress. This is the leading cause of spalling and cracking. The thermal expansion coefficient of graphite tells us how much the electrode will change size as it heats up. We want this number to be very low.

This is where the difference in raw material shines. Needle coke is a special type of coke with a needle-like structure. It has an incredibly low CTE. UHP electrodes rely heavily on needle coke to survive high-power operations. Using the right material to reduce the thermal expansion is the secret to superior shock resistance of graphite electrodes.

How Does Raw Material Selection Determine the Final Product Quality?

You cannot make a gold ring out of brass. Similarly, you cannot make a high power graphite electrode out of poor-quality carbon. The quality of graphite electrodes depends entirely on the raw material performance.

We use two main types of coke: petroleum coke and needle coke.

- Petroleum Coke: Used for standard electrodes. It is a solid by-product of oil refining.

- Needle Coke: The premium choice. It is expensive but essential for high power graphite and UHP grades.

High-quality petroleum coke serves as the backbone, but needle coke provides the structure needed for low CTE and high conductivity. The binder, usually coal tar pitch, acts as the glue. Graphite electrodes must be produced with a precise recipe. At Heyuan Carbon, we rigorously test every batch of raw material before it ever enters our production line. This ensures the final product meets the industry standards.

Why is Precision Machining of the Thread and Body Crucial?

A graphite electrode is rarely used alone. They are joined together to form a long electrode column. The connection point is the nipple (pin) and the socket. This joint is the weakest link.

If the machining of the thread is not perfect, gaps will form. Gaps increase electrical resistance. High resistance creates heat. Excessive heat causes the joint to oxidize, loosen, and eventually break. This is known as a high resistance junction.

The machining accuracy of the electrode body and the connecting pins must be flawless. We check the cross-sectional geometry and thread pitch with extreme precision. The electrode sections must screw together tightly but not so tightly that they crack under thermal stress. The connection must be equipped with connecting bolts (nipples) that perfectly match the electrode's thermal properties.

How Does the Graphitization Process Affect the Degree of Graphitization?

Manufacturing an electrode takes months. The most critical step is graphitization. This is where baked carbon is transformed into synthetic graphite. We load the carbon rods into a graphitization furnace and heat them to 3,000°C.

Increasing the graphitization temperature aligns the carbon atoms into an ordered, layered structure. This alignment is what gives graphite its unique properties: high conductivity, lubricity, and thermal resistance.

The degree of graphitization determines the final resistivity. A higher degree means better conductivity. It also impacts the thermal conductivity. Interestingly, while we want low electrical resistance, high thermal conductivity helps distribute heat evenly, reducing hot spots. Process technology in this stage is a closely guarded secret of top manufacturers.

What are the Differences Between RP, HP, and UHP Power Graphite Electrodes?

Graphite electrodes is divided into three main grades based on their power capacity and physical properties. Understanding these helps you buy the right tool for the job.

- RP (Regular Power): Made mostly from petroleum coke. Used in smaller, lower-power electric arc furnaces and ladle furnaces.

- HP (High Power): Contains some needle coke (around 30%). Used in medium-sized furnaces. High power graphite electrode grades offer a balance of cost and performance.

- UHP (Ultra High Power): Made almost entirely (or 100%) from premium needle coke. These are for the monsters—large, high-amperage EAFs. They have the lowest resistivity and linear expansion.

Power graphite electrodes are produced differently for each grade. Using an RP electrode in a UHP furnace leads to instant failure. Conversely, using UHP in a low-power application might be a waste of money. We help clients align the tensile strength and thermal conductivity of the grade with their specific furnace parameters.

How Do We Test Finished Products Before They Leave the Factory?

At Heyuan Carbon, we believe that trust is good, but control is better. Before any finished products are shipped to a customer like Peter in Germany, they undergo a battery of tests.

We sample the batch and verify:

- Resistivity: Using the voltage drop method.

- Bulk Density: Weighing and measuring volume.

- Strength: Breaking samples to test flexural strength.

- Ash Content: To ensure purity.

- CTE: Checking expansion rates.

We also perform a physical inspection of the surface. We look for cracks, chips, or voids. We check the thread tolerance with "Go/No-Go" gauges. This ensures that the graphite electrodes in use will assemble easily and perform reliably. Graphite is a very important investment for a steel mill, and we treat it with that level of respect.

Summary

To summarize, judging the quality of a graphite electrode requires a look at the data sheet and the manufacturer's history. Here are the key points to remember:

- Resistivity: Lower is better. It means efficient flow of electric current and less overheating.

- Density: A balance is needed. High density improves strength and oxidation resistance but must not compromise thermal shock resistance.

- Raw Materials: Needle coke is essential for high power graphite and UHP grades to lower the CTE.

- Machining: Precise threads prevent joint failure and high stress concentration.

- Grades: Choose the right grade (RP, HP, UHP) for your specific furnace power level.

- Supplier: A reliable partner like Heyuan Carbon uses strict testing to measure the quality of graphite before it ever reaches your dock.

Choosing the right UHP Graphite Electrode or Graphite Electrode Nipples is critical for your success. By understanding these parameters, you ensure your steel production is efficient, safe, and profitable.

Post time: 12 月-11-2025